A DIY TVOC & eCO2 sensor for integration into Home Assistant using ESP-Home.

Project Outline

A DIY Total Volatile Organic Compounds (TVOC) and equivalent Carbon Dioxide (eCO2) sensor to measure the air quality within my room. This is particularly important

due to the recent addition of a 3D printer within the space. I'd also like this sensor to be able to connect to my Home Assistant instance to be able to consolidate and

manage it alongside existing smart home sensors.

Components

-

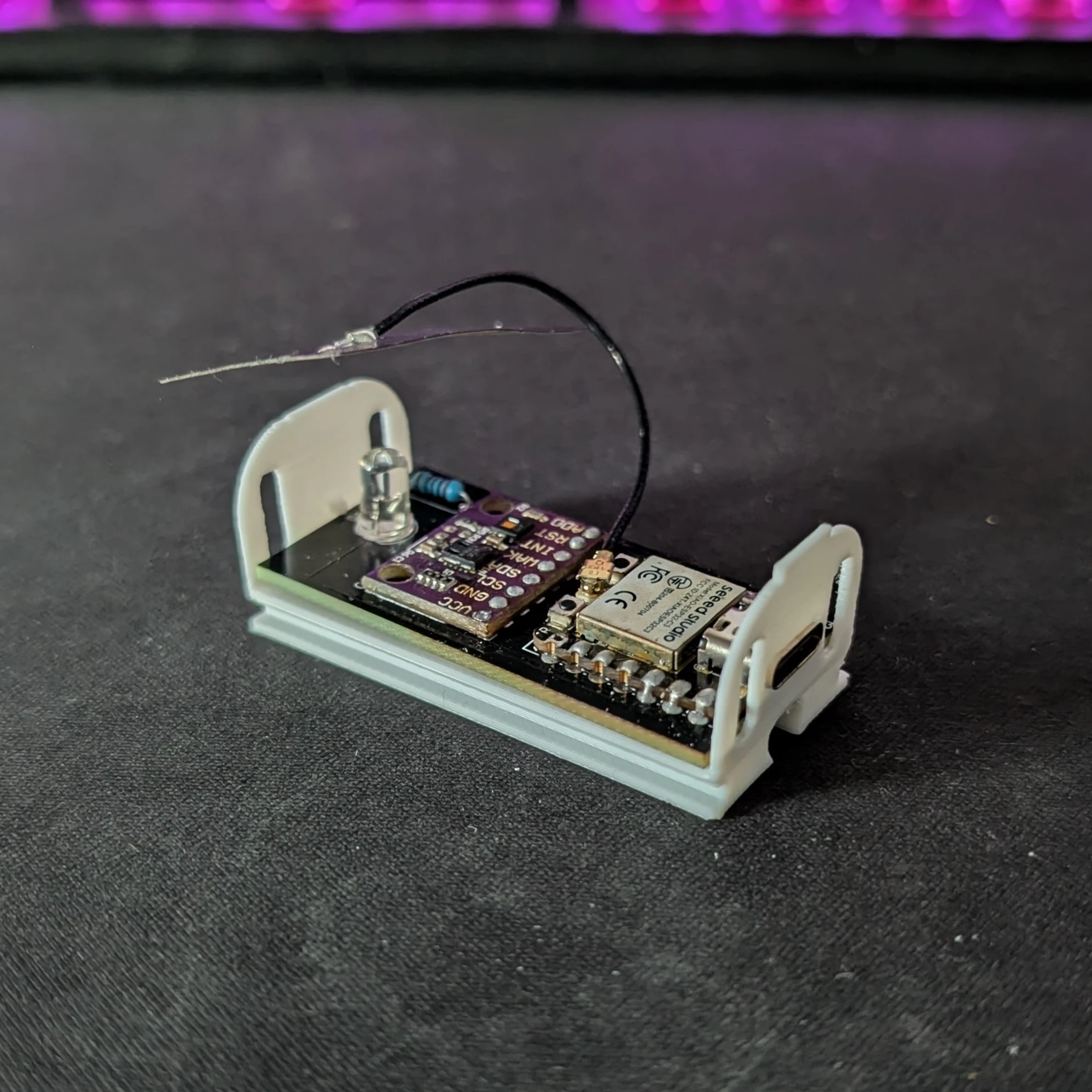

- Seeed XIAO ESP32C3 board

-

- CCS811 HDC1080 eCO2 and TVOC sensor

-

- Custom PCB

-

- Blue LED

-

- 100 ohm resistor

- 3D Printed enclosure

Prototype

Built using a breadboard. The ESP board communicates with Home Assistant via ESP-Home and controls power input and distribution. The TVOC/eCO2 sensor is wired up to the ESP board and reports the current TVOC and eCO2 values every 15 seconds. The Blue LED acts as a status light and flashes when the device is disconnected from the Home Assistant instance but can also be toggled manually from the Home Assistant dashboard.